Engagements

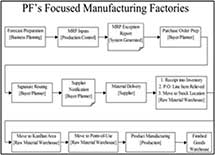

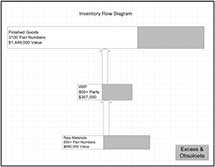

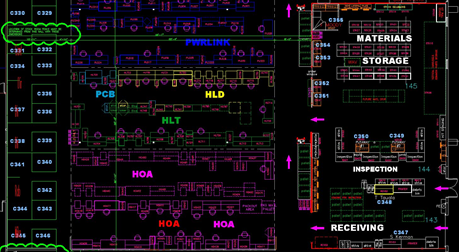

DeHart Consulting has conducted operations and supply chain strategy, facility design, and business process re-engineering engagements in industries as varied as semiconductors and sporting goods, but the vast majority of our manufacturing management consulting experience is in the electronics and photonics space. DeHart Consulting's consultants have designed lean manufacturing, focused factories for the assembly of photonic amplifiers, assembled supply chains for high-volume electronic sub-assemblies, and created software for the implementation of demand-pull materials management systems.

The thread running through this body of work is our belief that the success of any consulting firm is pinned to the success of its clients and we strive to help them out-learn and outperform their competitors. We have found that when companies couple their internal manufacturing operations knowledge to our external lean manufacturing consulting knowledge, great things result!