Demand-Based Production from a Work-Volume Perspective

When looking at authorizing work in upstream stages of production, the traditional Kanban system establishes quantity buffers, or queues, at each WC. Then when the buffer quantity hits a minimum value (the Queue Policy), the Kanban card is returned to its originating WC for replenishment. While this unit-quantity buffer does not work well in a high-variety production environment (Suri, et al), the concept of a Queue Policy can still be a useful management tool if expressed in work-hours as opposed to unit-quantities.

Within the present demand-pull system, the concept of a manageable Queue Policy is coupled with the demand flow concept, to create a management framework for setting inventory levels for the queues at each WC. Described herein are a WC buffer, or queue, and a "policy" that provides for adjustment of the inventory in the factory. For this reason, the WC is conceptualized as a two-part entity in the figure below, the Queue and the Work-in-Process (WIP) area, and a goal herein is to minimize the hours in the Queue and maximize throughput.

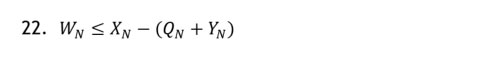

With FAFP processing in mind, this trigger can be expressed mathematically for any given WC "N" (WCN), except the first WC in a production process, as follows:

Or

Where all variables are specified in the Table of Definitions.

When this inequality is true, a Pull-tag is assigned to WO1. Or, more completely, an upstream pull-authorization will be attempted on WO1 whenever the amount of work in WCN's queue plus the work upstream that has already been authorized and destined for WCN is less than the Queue Policy (XN). But the pull-authorization will not be completed, and a PT assigned, unless the amount of work represented for WCN by WO1 (WN), when added to the current queue (QN) and currently-authorized UA WOs (either in UA queues or in UA WIP) (YN) will not exceed the Queue Policy, XN.

Assigning a precise value to the Queue Policy (XN) can now be accomplished within the algorithmic context of set forth the Article Calculating Flow Time in a Work Center.