An Optimum Queue Policy

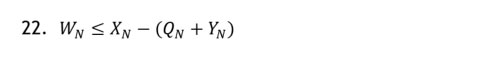

The formulae from Demand-Based Production from a Flow-Time Versus Need-Time Perspective and Demand-Based Production from a Work-Volume Perspective can now be combined to solve for the Queue Policy (XN). From Demand-Based Production from a Work-Volume Perspective, equation 22:

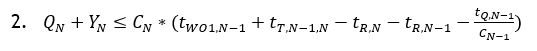

From Demand-Based Production from a Flow-Time Versus Need-Time Perspective, equation 2:

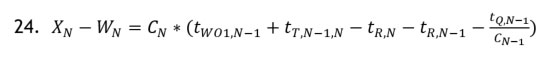

Therefore:

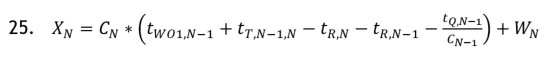

and the Queue Policy for WCN is given by:

From Demand-Based Production from a Work-Volume Perspective, this value of XN can be used to assign a Pull Tag to WO1 when the sum of its Clear Time in WCN (WN) + the queued Clear Times in the WCN queue (QN) + the sum of the Clear Times at WCN for all authorized UA WOs' (YN) is less than or equal to that value of XN. This formula, in the limit where all flow-times are 0, sets a "floor" of WN hours, which is needed to avoid "starving" a WC by setting a maximum Queue Policy that is less than the number of hours represented by the next WO to be authorized. All of the stated terms are "knowable" quantities within the construct of most ERP/MRP systems so that this construct is easily implementable.

The question can be raised as to why the formula from Demand-Based Production from a Work-Volume Perspective is re-introduced to define a pull algorithm, or why the flow formula (Equation 2 above) cannot just be used to assign Pull tags. The answer is primarily a matter of visual management in a lean environment. The concept of a maximum Queue Policy is a manageable and understandable concept in the factory environment and one for which the present technology provides management over-rides and/or adjustment factors to accommodate the realities of variability in the individual WCs. This pull-system conforms to the idea that when inventory falls below a pre-determined policy level, a replenishment signal is sent, yet at the same time, by using ideal flow times, it is forcing queued inventory toward zero.